Product

CNC controller

800S Package

Provides a complete CNC system that can configure 3-axis milling, with unrivaled price competitiveness and easy setup.

Details

Do you want a CNC with the highest performance MDI at the lowest price? This is the TURBO 800S package.

1. 800S package composition

2. 800S package features

- EtherCAT network adoption

- Look ahead, first look ahead block, basic 100 blocks (Max. 1000 blocks)

- High-speed processing function provided as standard (G10.3)

- Position control cycle minimum 0.5msec

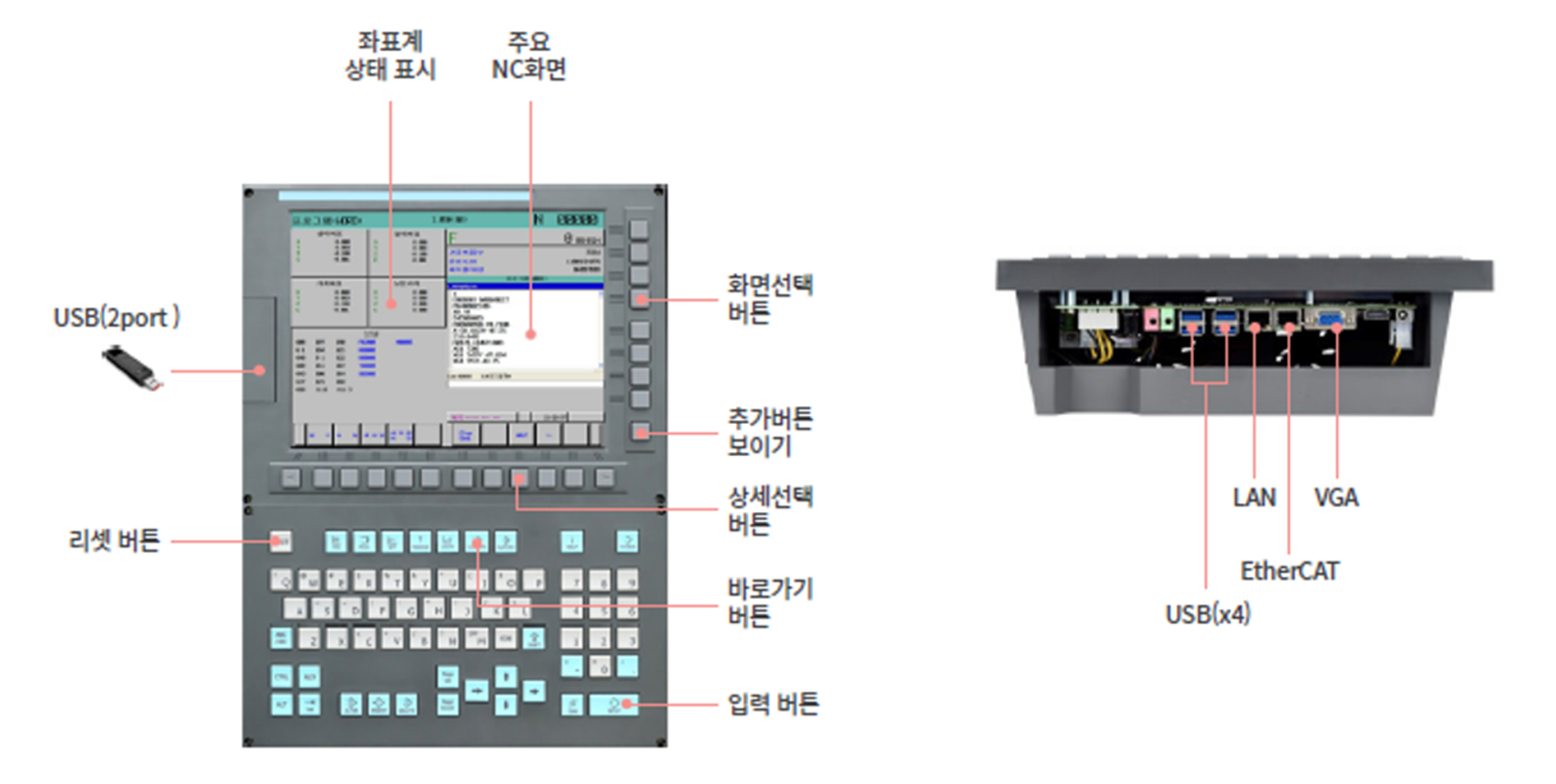

- Space-saving compact MDI and keyboard unit (vertical, horizontal)

- Secure connectivity with all desired peripherals

Items | Specification |

MDI unit | - 12.1’’ 1024 x 768 TFT-LCD (Touch Screen Option) - Provides basic Fanuc style HMI screen - USB 2 ports |

NC unit | - Industrial 2.3 GHz CPU - Number of control axes: Max.32, number of simultaneous control axes: 9 axes (XYZ-ABC-UVW) - Maximum score: IO 1024/1024 (expanded in units of 32 contacts), DEIO7246 for OP - RS-232/485, 2xSATA II - Supports GbE Ethernet 2 port |

SW | - OS: Windows XP Pro/Embedded/Win7 supported - Supports HX-MC (for milling and engraving machines), HX-TC (for lathes), HX-CUT (for cutting machines), and HX-EDM (for electric discharge machines) - Language (Korean/English/Japanese/Chinese/German) support - Windows-based HMI: HMI Editor allows user-specific functions and screen configuration (Option) - Provides high-speed/high-precision transfer function through feed forward/look ahead functions - Friction. High-precision control function through backlash and pitch error correction - 3D graphic path inspection and real-time processing path monitoring function - Multi-axis servo synchronous control function (Gantry, twin table control) - Supports various program formats (G code, DWG, DXF) - Minimum setting unit 0.001mm, 0.001deg, 0.0001inch - Up to 12 digit command possible (±99999999.999) |

Option | - 4 channels of PWM output (electrical discharge machine, laser cutter, etc.) - AD 4 channels (12bit, various sensor inputs possible) - 4 channels of high-speed input contacts (high-speed skip function, measuring instrument support) - System control support (2/4/6 channels supported) - Multiplier for sine wave encoder (Max. 400 multiplier) - Dual encoder feedback function (optional) - Absolute encoder interface (Yaskawa ΣV drive) |

3. Servo motor / servo drive

| High-torque servo motor (SMG-Series) / High-responsive servo drive (SD-Series) Application field * Machine Tool * Robots * Automotive Industry * Semiconductor Manufacturing * Inspection Machine * Pharmaceutical * Material Handling * Logistics * Packing Machine * AGV * Wafer/Flat Panel Transfer |

4. Applicable equipment video

Specifications

1. Peripheral device connection and function module

|

Function module | Specification |

AIB3.0 | Analog servo 3 Axis, 6 Axis Pulse servo 3 Axis, 6 Axis DAC : For spindle command (+-10V) EtherCAT communication PWM (optional) |

EDIO72/46 | Digital Input/Output 72/46 contacts DAC : For spindle command (+-10V) QEP : Encoder pulse counter 2ch. (for MPG & Spindle) EtherCAT communication |

EDI32/EDO32 | Digital Input32/Output32 contacts Size : 130x40x20 EtherCAT communication |

2. CPU Specification

| CPU | Equipped with (+-10V) Intel Cel-1037U 2.3GHz for spindle command, (Option: I5-3317U 2.6Ghz available) |

| DISPLAY | 10.4” Color TFT LCD(1024*768) |

| Number of control axes | Max.32 |

| USB PORT | 2 front USB2.0, 2 rear USB3.0, 2 USB2.0 |

| Serial port | (4 options available) |

| ETHERNET | GIGABIT ETHERNET 1-PORT (EtherCAT only 1PORT) |

| STORAGE | SSD 32GB ( Option 64GB, 256GB ) |

| MEMORY | DDR3 4GB, ( Option 8GB ) |

| Language | Korean, English, Japanese, Chinese, German |

Download

| Division | File name | Download |

|---|