Product

CNC controller

CPACK

Up to 32-axis full synchronous/interpolation control

Up to 1024 IOs contacts (32/64 point unit expansion possible)

Details

Powerful multi-axis motion controller for automation equipment

1. CPACK configuration and features

* Provides powerful multi-axis motion controller function

* Provides high-performance control functions at the lowest cost through PC-based motion control software

* No additional HW required to run customer applications

(Can be operated with a GUI implemented on the customer’s PC)

* No need for a PC equipped with a separate PLC and motion card

* Windows-based host programming is possible in general-purpose C (or C++, C#) language, and a powerful API is provided to support this.

* Built-in real-time system, performs fast and accurate operation

* Real-time control of servo motors & drives and IO contacts where the upper host control program and shared memory are connected through TCP/IP communication and lower EtherCAT communication

* Provides the best performance and optimal scalability at the best price

|

2. Example of application of automated assembly process line

- Can be used as a controller for OLED process equipment

- CCD vision alignment and inspection function programmable

- The number of axes for each station can be expanded in 6-axis units, and IO expansion can be expanded in 32/32 units.

|

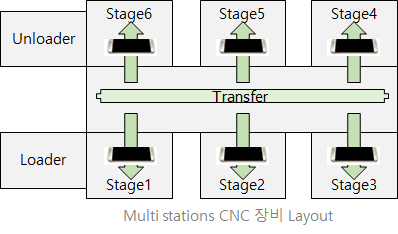

3. Application example of Multi-Stations CNC control system for precision machining

- Application of component alignment vision to improve productivity by distributing to multi-stage

- Up to 32 axes fully synchronous/interpolation control

- Provides up to 1024 IOs contacts

- Supports high-speed host controller TCP/IP communication by directly accessing shared memory

- Provides API for Windows-based host programming and can use general-purpose C (or C++, C#) language

4. Application example of a measurement system connected to a non-contact X-ray thin film thickness gauge

- FPCB material Pre-Align -> Loading -> Measurement Stage -> Unloading batch processing automation equipment

- Programmable in conjunction with CCD vision alignment and non-contact X-ray inspection system

- Dual screen allows you to see vision alignment/measurement inspection progress at a glance

- Total 6 axis servos, 5 stepping motors, 64/64 IOs

|

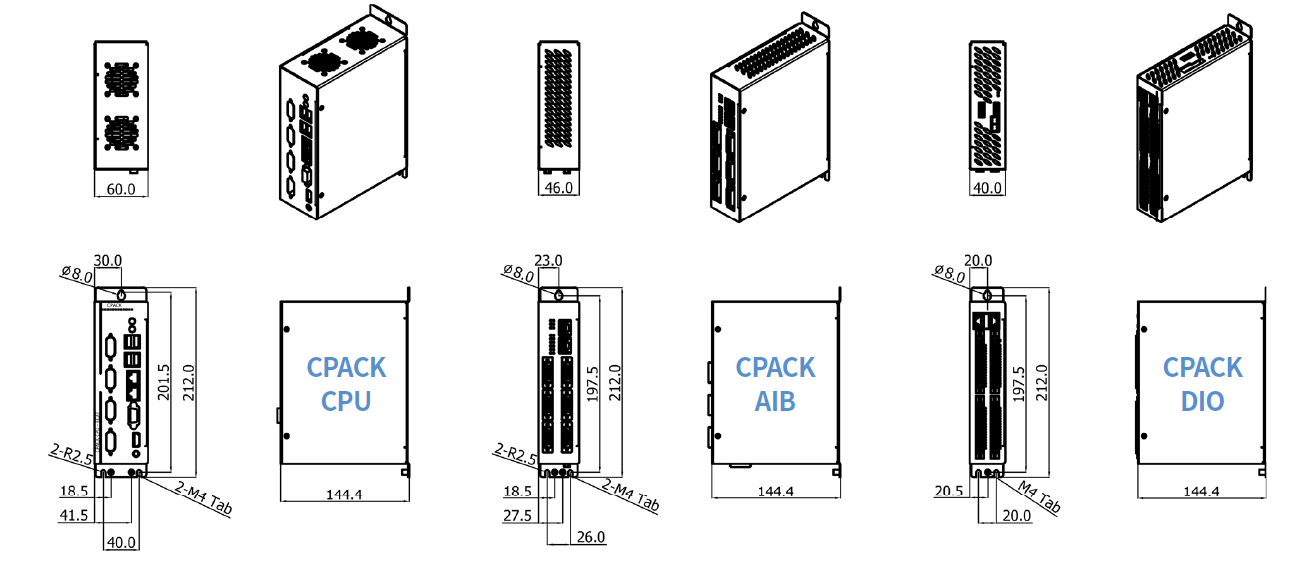

5. CPACK Dimensions

|

Specifications

1. Peripheral device connection and function module

Function mudule | Specification |

AIB3.0 | Analog servo 3Axis, 6Axis Pulse servo 3Axis, 6Axis DAC : For spindle command (+-10V) EtherCAT communication PWM (optional) |

EDIO72/46 | Digital Input/Output 72/46contacts DAC : For spindle command (+-10V) QEP: Encoder pulse counter 2ch. (for MPG & Spindle) EtherCAT communication |

EDIO64/64  | Digital Input/Output 72/46 contacts EtherCAT communication |

EDI32/EDO32 | Digital Input32/Output32 contacts size : 130x40x20 EtherCAT communication |

| Sensor | Ethernet RS-232C/485 |

MPG | Power 4.75V~5.25V Response frequency: 0~5kHz Output type : Line Driver External dimension : W70X H160 X D50 |

Vision  | Ethernet RS-232C/485 |

2. CPU 사양

| CPU | Equipped with Intel Cel-1037U 2.3GHz, (Option: I5-3317U 2.6Ghz available) |

| DISPLAY | 10.4” Color TFT LCD(1024*768) |

| Number of control axes | Max.32 |

| USB PORT | Front USB3.0 x 2, USB 2.0 x 2 |

| Serial port | 1 RS-232C (3 options available) |

| ETHERNET | GIGABIT ETHERNET 1-PORT (EtherCAT only 1PORT) |

| STORAGE | SSD 32GB ( Option 64GB, 256GB ) |

| MEMORY | DDR3 4GB, ( Option 8GB ) |

| Language | Korean, English, Japanese, Chinese, German |

Download

| Division | File name | Download |

|---|