Product

LMS (Linear Motion System)

LMS (Linear Motion System)

High-speed precision transfer, economical design and easy installation

40N~1000N, Max. 2m/sec

Details

High-speed-Detailed-movable Linear Motion System

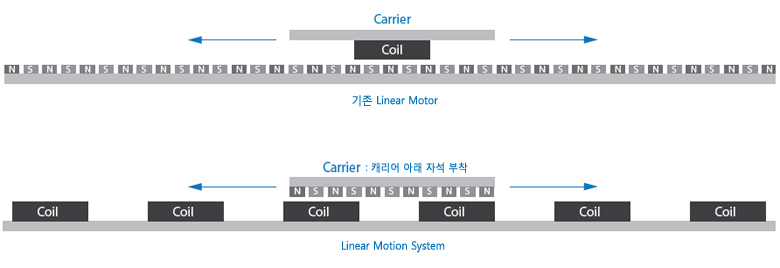

1. LMS introduction

- Carrier motion is achieved by sequentially activating the coils.

- The linear coil is fixed, making cable work simple. (Cableveyor is not required, when applying a vacuum chamber, the cable within the chamber disappears)

- Cost savings as linear encoder is not used.

- Ease of logistics configuration: Easy connection between individual transport units and logistics design.

2. Gap between Linear Coil and Magnet (Air Gap)

3. LMS Configuration

4. Encoder Resolution

5. LMS Video

Test video of logistic line

Test Video of synchronous control

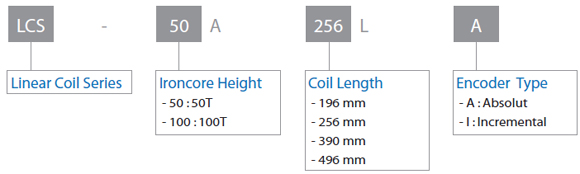

6. Linear Coil product format

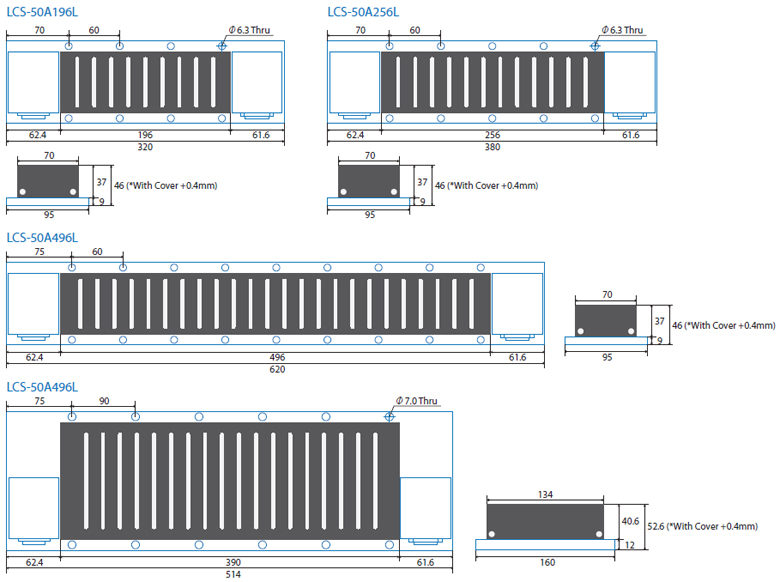

7. Linear Coil Dimension

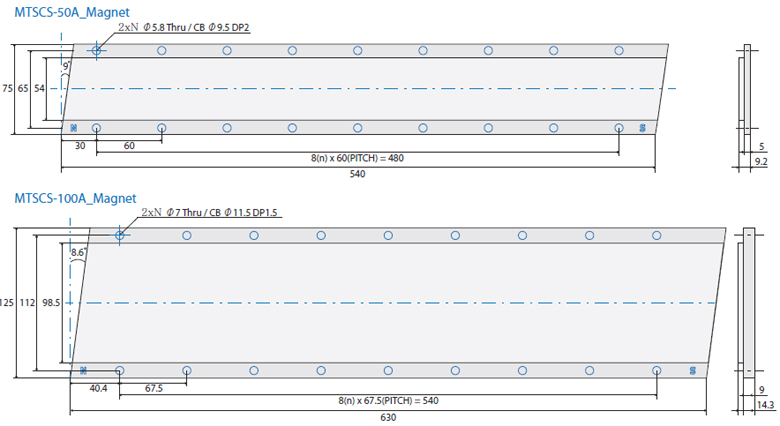

8. Magnet Track Dimension

Specifications

Linear Coil Spec

| SPEC | LCS SERIES | ||||

| 50A196L | 50A256L | 50A496L | 100A390L | ||

Force (N) | Continuous | 230 | 350 | 750 | 1000 |

| Maximum | 600 | 800 | 1500 | 3000 | |

| Current (Arms) | Continuous | 2.26 | 4.5 | 8.52 | 9.29 |

| Maximum | 5.75 | 11.5 | 18.5 | 27.8 | |

| Resistance (Ω) | 5.67 | 6.01 | 6.72 | 1.96 | |

| Inductance | 34.01 | 34.26 | 35.05 | 12.31 | |

| Back EMF | 34.8 | 23.2 | 23.2 | 37.5 | |

| Force Constant (N/Arms) | 100 | 65 | 65 | 108 | |

| Capacity (W) | 400 | 750 | 1800 | 3000 | |

| Drive Capacity (W) | 400 | 1000 | 2000 | 3000 | |

| Encoder | ABS or Incremental | ||||

| Maximum Speed | Over 2m/sec | ||||

* Product specifications and dimensions may change to improve performance.

Download

| Division | File name | Download |

|---|