Product

Metal 3DP (PBF)

Introduction to Metal 3D Printer types

Details

* The process of designing and testing automotive production parts can be repeated quickly and efficiently. * The strength and weight of parts can be precisely controlled to effectively manage inertia, improve geometry, and maximize performance, thereby increasing production capacity. * The design and production of parts can be done more efficiently than conventional machine cutting processes, enabling rapid verification and optimizing quality.AnyX-Series 제품 유형 소개

1. Dental Parts

* No other dental processing equipment can compare. * We can produce all kinds of tooth shapes (prosthetics) with various materials such as Stainless, Titanium, Maraging Steel, Nickel Alloy, Cobalt chrome, Aluminum, etc. * Reduces unit cost of parts and improves productivity, allowing you to fulfill your orders more quickly and accurately. |  |

2. Power Turbine Parts

* Cost-effective additive manufacturing for aerospace applications Increases productivity. * Enables production of complex parts that are impossible to produce with conventional machining methods. * Enables metal 3D printed parts with superior material properties with the best surface quality |  |

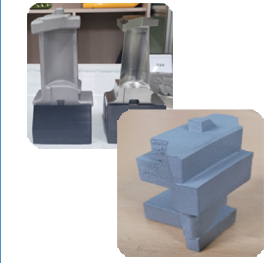

3. Nuclear SMR Parts

* It is possible to design, manufacture, and improve stability of precision parts with complex structures such as nuclear reactors without joints. * It is possible to manufacture nuclear pressure vessels for neutron absorption in nuclear power plant systems using powders such as ceramics and carbon composites. * It is possible to manufacture large nuclear power plant parts up to 1m in size. |  |

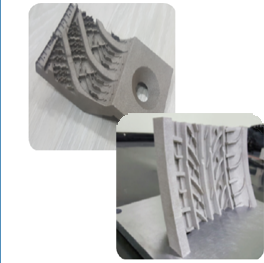

4. Tire Mold Parts

* Production of complex shaped tire mold parts and customization of customer- specific production is possible. * Rapid development and testing of complex tire and wheel designs using a variety of materials at low cost. * Wide range of material selection and freedom from the constraints of conventional machine cutting processing. |  |

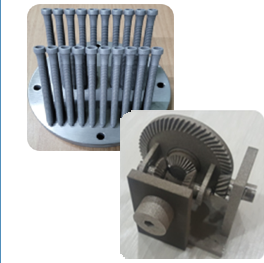

5. Automotive Parts

* The process of designing and testing automotive production parts can be repeated quickly and efficiently. * The strength and weight of parts can be precisely controlled to effectively manage inertia, improve geometry, and maximize performance, thereby increasing production capacity. * The design and production of parts can be done more efficiently than conventional machine cutting processes, enabling rapid verification and optimizing quality. |  |

Specifications

Download

| Division | File name | Download |

|---|