Product

Metal 3DP (PBF)

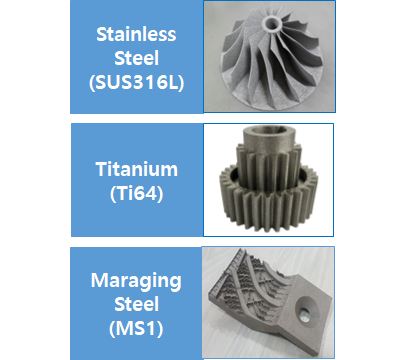

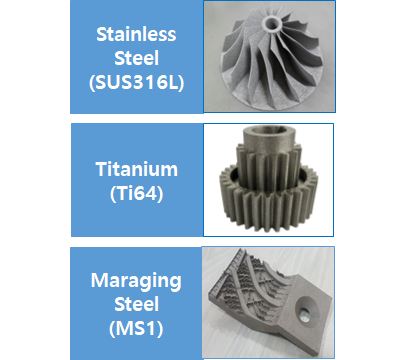

Powder Materials for Metal 3DP

Details

Introducing materials exclusively for the AnyX-Series metal 3D printer.

1. Stainless Steel

* SUS316L is a chromium-nickel-molybdenum austenitic stainless steel, which has high corrosion resistance compared to the most common stainless steel 304, and has no significant disadvantages in terms of cost. * By adding molybdenum, this steel is particularly suitable for components in harsh chemical environments containing chlorides and other halogens. * Typical applications can be found in a wide range of industries such as plant engineering, oil and gas industry, automotive, medical technology, jewelry and mold components. * SUS316L is easy to weld and offers excellent ductility and high creep strength at high temperatures. |  |

2. Titanium

* Titanium (Ti) and its alloys are generally used extensively in many industries due to their low density and high corrosion and oxidation resistance. * Titanium alloys are used in additive manufacturing to produce a wide range of industrial components, including blades, fixtures, rings, discs, hubs, and vessels. * Titanium alloys are also used to produce high-performance racing engine components, such as gearboxes and connecting rods. * Because of their proven biocompatibility and long history in the medical industry, they are an established material for medical applications, such as medical implants. |  |

3. Maraging Steel

* The M300 parameters of the Concept Laser M2 Series 5 have been developed to leverage the performance of the previous M2 generation. * The basic parameters provide excellent surface quality while maintaining very good density, mechanical strength and productivity. * The surface parameters have been developed to achieve the best overall surface quality and best part resolution. * The productivity parameters are available to process with rubber or steel recoaters to maximize build speed. * The hybrid parameters combine surface and productivity parameters and can significantly increase productivity for parts with high volume/surface ratios while meeting the highest surface quality requirements. |  |

Specifications

Download

| Division | File name | Download |

|---|